MEIKO BOOTH

HOST MILAN 2025

THE MEIKO VISION: FUTURE-PROOF THROUGH INNOVATION

Staff shortages, rising operating costs, new guidelines and trends – flexibility is essential in the hospitality industry. Our solutions are designed to take the pressure off you so that you can concentrate on what matters most: your guests and employees.

The MEIKO Vision: future-proof through innovation means for us:

- We strive to offer the latest dishwasher technology.

- What we develop should be in line with the concept of sustainability (e.g. reducing consumption)

- Equipment and features are inspired by trends such as connectivity, sustainability and health.

- Our solution is embedded in the MEIKO Clean Solution Circle.

Dive into the world of MEIKO and discover our diversity.

COMING NEXT YEAR

The new MEIKO R-series

Rack type dishwashing machine are true classics in many dishwashing areas around the world. Our latest development will be launched next year, stay tuned for the next must-have from MEIKO.

We took a peek into the laboratory and can now reveal:

Our new rack type dishwashing machine has...

- a compact machine design, especially for small dishwashing areas

- lots of premium features and improved ergonomics

- has a high efficiency and can reduce operating costs (including through savings in water and chemicals).

- has lower noise emissions.

Curious? Welcome to Milan!

MEIKO GREEN MEETS MEIKO CLEAN

Why is technology needed to collect and treat kitchen waste and food waste?

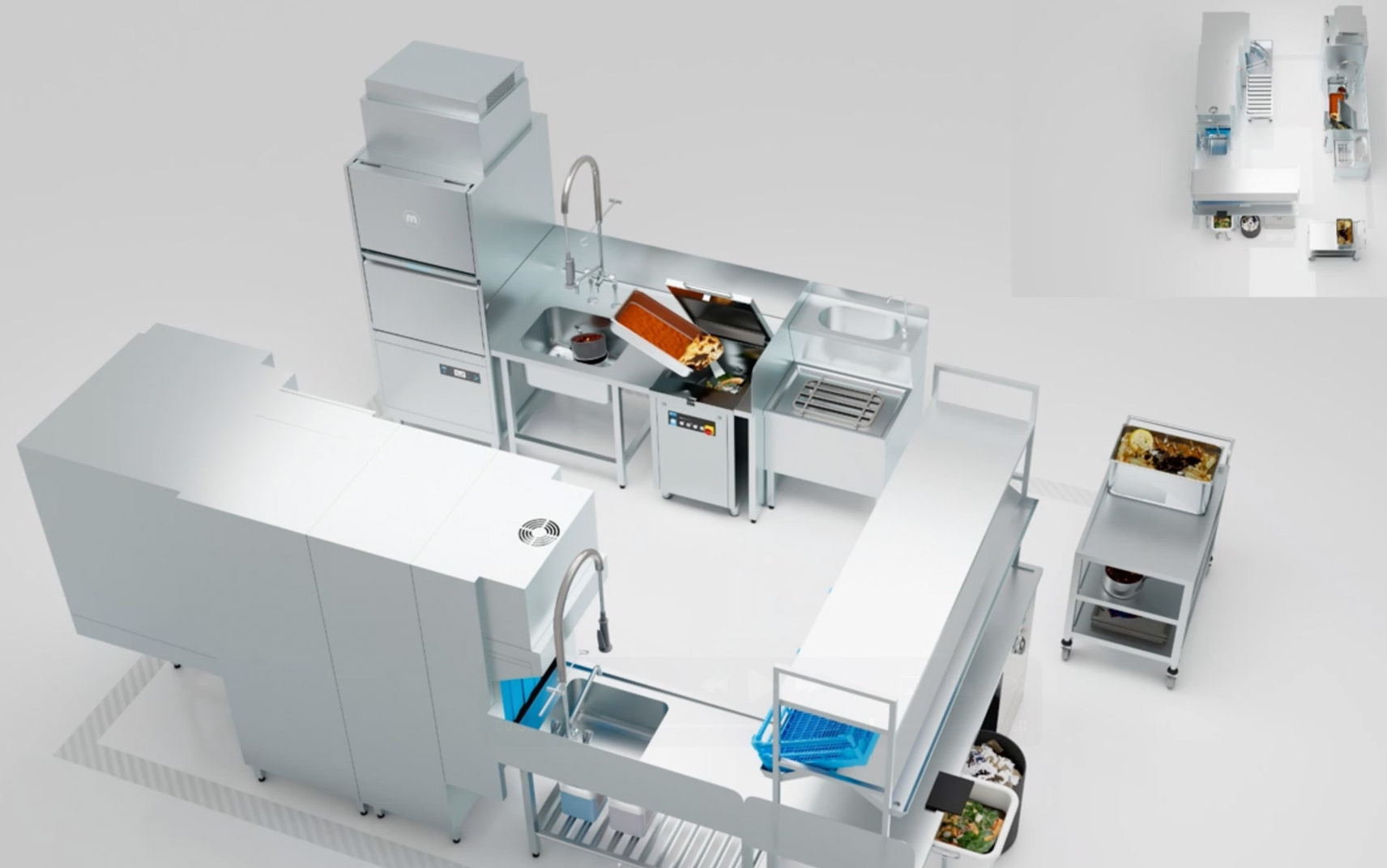

At the HOST trade show, we show why food waste is valuable and why integrated food waste treatment systems belong in almost every food service dishwashing area.

FOOD WASTE TREATMENT SYSTEM

- simplify processes (automation)

- reduce the workload for staff (no need to carry food waste bins)

- improve hygiene (food waste in a closed system)

- can reduce costs (depending on the system compared to the previous solution, e.g. cooling the bins)

MEIKO GREEN meets MEIKO Clean is our concept

We are pleased to present it at HOST!

MEIKO M-iFlow IPB

better by automation

Finding staff for the dishwashing area in commercial kitchens is a challenge. At the feeding section of a flight type dishwashing machine, napkins must be removed from the tray, food waste scraped off and the dishes loaded.

WE SET A NEW MEIKO MILESTONE.

With the automation module MEIKO M-iFlow IPB

- you can reduce personnel needs at the feeding section by up to 50% (compared to an identical M-iQ flight type dishwashing machine without M-iFlow IPB)

- The dishes are automatically turned, pre-cleaned and any food waste is removed.

- Dishware is placed in the appropriate shafts easily, quickly and ergonomically which is good for the staff.

- Trays and dishes are automatically conveyed onwards, washed and collected

Look forward to a solution that offers attractive cost-effectiveness, efficiency, hygiene and ergonomic relief for your staff, providing the ideal combination for sustainable washing cycles.

Our AI-supported automation study, which we are presenting at the trade fair, shows what this could look like.