TRAY

WASHER

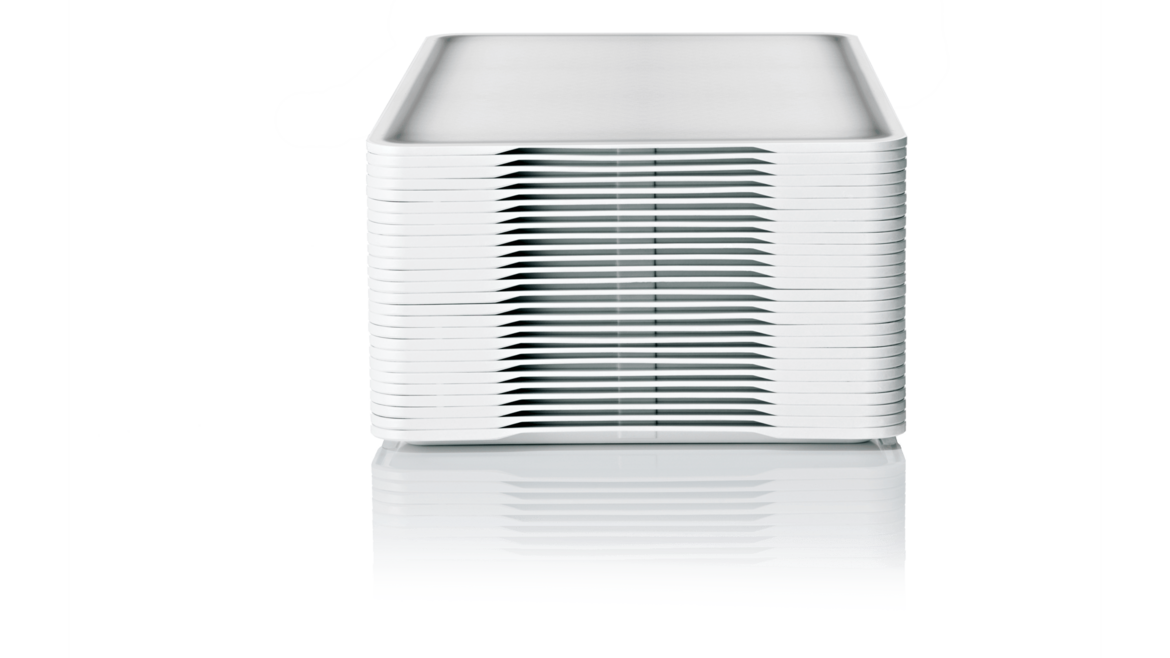

MEIKO BTA

Quick, reliable and efficient: the BTA was designed for one job – it transports trays to the wash chamber on a conveyor, washes them, dries them and stacks them. All automatically. This saves time, hand contact, energy consumption and operating costs.

And the tray guides are easily adjustable should you wish to change what kind of tray you wash at a later date.

THESE FEATURES

are what make the MEIKO BTA so special

The conveyor splits before the drying section: the trays are therefore transported on dry round belts when in the drying zone (after the final rinse).

Advantages:

• Optimum drying results

• No manual polishing

• Low-wear, low-maintenance round belt conveyor system

Clear icons and alerts make the machine easy to operate and make it easy to communicate with our customer service team.

Advantages:

• Convenience of fully electronic operation

• Reduces the time, effort and expenditure required for maintenance

A signal light comes on when the tray stacking trolley is nearly full. Four to eight trays can be collected on the intermediate stacker before the new trolley is put in place.

Advantages:

• Prompt and safe switching of the tray stacking trolley

• With no interruption or disruption to operations

The washing system is located above and below the tray. This is followed by an intensive hot fresh water final rinse of each tray.

Advantages:

• Optimum washing result from start to finish, with no exceptions

• Greater hygiene safety, down to every last nook and cranny

Vapour is constantly extracted, keeping conditions pleasant for those working in the dishwashing area. The integrated heat recovery system (optional) channels the heat energy from the exhaust air back into the dishwashing machine.

Advantage:

Reduces the humidity and temperature of the exhaust air

HIGH-

PERFORMANCE

With exceptional operational reliability

Dynamic high-performance pump

Intensive washing system

85 degree final rinse with fresh water

Specialist high-performance fan

Low-wear round belt conveyor system

CLEVER

thanks to our considered design

A gravity-supported sliding door ensures easy access to the wash, rinse and drying zones, and to the heat recovery system.

The compact design is ideal for tailored kitchen planning and for integrating into new semi-automatic dishwashing systems, or retrofitting into existing systems.