BUILDING THE INFRASTRUCTURE FOR REUSE

Re:Dish was founded with a bold mission: to tackle the more than 1 trillion single-use foodservice products — such as paper plates and disposable coffee cups—that end up in U.S. landfills every year. While reuse was once common practice, convenience slowly pushed foodservice toward disposable products, creating an enormous environmental challenge.

By supplying reusable food and beverage ware, delivering it to customers, collecting it after use, professionally washing and sanitizing it, and then putting it back into circulation, Re:Dish has created a closed-loop system that enables large institutions to move away from single-use products without adding complexity to their operations. Their customers include universities, hospitals, corporate cafeterias, stadiums and more—organizations that historically relied heavily on disposables.

A WAREWASHING OPERATION DESIGNED FOR HIGH VOLUME

At its core, Re:Dish operates as a highly efficient warewashing facility supported by intelligent processes and tracking technology. Since opening its first facility in 2022, Re:Dish has expanded to three U.S. locations—New York, Boston, and Philadelphia—with plans for continued growth nationwide.

To support this model, Re:Dish needed warewashing equipment that could withstand constant, heavy-duty operation, deliver consistent results, and align with their sustainability goals.

FINDING THE RIGHT PARTNER IN MEIKO

After being introduced to MEIKO through a sales representative, the Re:Dish team visited catering operations already using MEIKO equipment. What they saw stood out immediately.

They were impressed by how reliable the machines were and how well they handled heavy usage all day, every day. That’s exactly what Re:Dish needed.

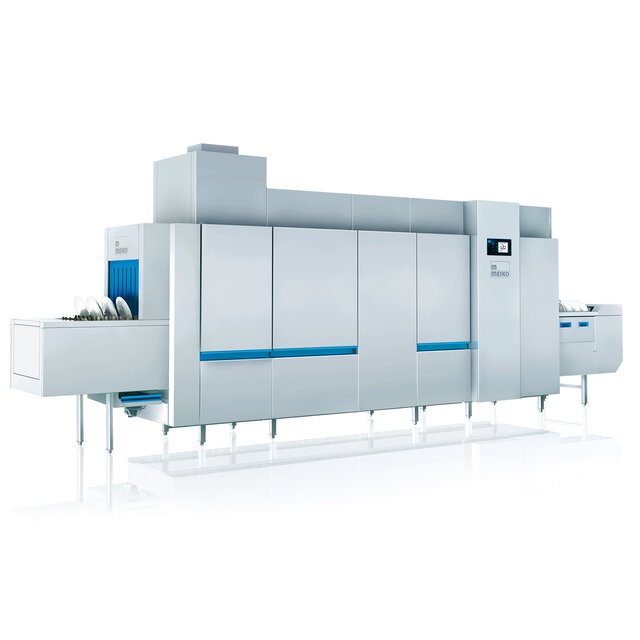

Re:Dish ultimately selected the MEIKO M-iQ Cup, a flight type dishwasher designed specifically for high-volume cup and plastic ware applications.

SOLVING ONE OF REUSE’S BIGGEST CHALLENGES: DRYING POLYPROPYLENE

Re:Dish primarily uses polypropylene reusables—a durable, food-safe material free from BPA and other forever chemicals. While ideal for reuse in foodservice, polypropylene presents a major challenge in warewashing: it is notoriously difficult to dry.

With Re:Dish washing tens of thousands of polypropylene items each day, effective drying wasn’t optional—it was mission-critical.

The MEIKO M-iQ Cup provided the solution.

The machine features a unique vibration drying zone, where the conveyor gently shakes excess water droplets from the ware, combined with automated rinse aid for enhanced results. This creates an exceptionally effective drying process for plastics that are traditionally difficult to dry.

The MEIKO M-iQ Cup machine is a great solution for anyone using polypropylene

— Caroline Vanderlip, Founder & CEO, Re:Dish

ONE CONVEYOR. BETTER RESULTS. LOWER IMPACT.

Prior to installing MEIKO equipment, Re:Dish relied on systems that required separate drying steps, adding time, labor, and valuable floor space to their operation. The M-iQ Cup changed that entirely.

With MEIKO, Re:Dish can now wash, sanitize, and dry in a single pass on one conveyor.

“MEIKO has helped us with a lot of our challenges. Its biggest impact is that it improved our throughput, improved our consistency, reduced our energy use, and reduced our water use.” Tom McCarthy, Innovation & Facilities at Re:Dish.

The operational benefits quickly translated into measurable sustainability gains. When Re:Dish analyzed their overall environmental impact, they saw significant improvements—reinforcing that MEIKO was the right long-term partner.

We believe that MEIKO is the best fit for what we are trying to achieve, and that has not wavered at all

Caroline Vanderlip

SUPPORTING GROWTH, SUSTAINABILITY, AND LABOR EFFICIENCY

Since launching in 2022, Re:Dish has washed more than 7.5 million reusable items, diverting the same number of single-use products from landfills—and that number continues to grow each month.

MEIKO’s impact extends beyond sustainability.

MEIKO has had a significant impact on our labor. Without the M-iQ Cup, I would need three to four times more labor. The machine significantly reduces the number of steps required to get our reusables clean and ready for reuse.

Tom McCarthy

The powerful drying system—featuring automated rinse aid and vibration drying—eliminates the need for additional handling, time, or labor.

Tom also highlights the reliability of the equipment and the strength of MEIKO’s service support.

The service with MEIKO is second to none. Their technicians are always ahead of schedule and proactive in making sure we have what we need. The equipment itself has been extremely reliable.

A PARTNERSHIP BUILT ON SHARED VALUES

For Re:Dish, choosing MEIKO wasn’t just about performance—it was about alignment.

Re:Dish was founded to make a global environmental impact, and MEIKO’s longstanding commitment to sustainability resonated deeply. From reducing energy and water consumption to designing machines built for longevity, MEIKO’s ethos closely mirrors Re:Dish’s mission.

We couldn’t do Re:Dish without MEIKO. We are reliant on these machines to really deliver our business

says Caroline Vanderlip.